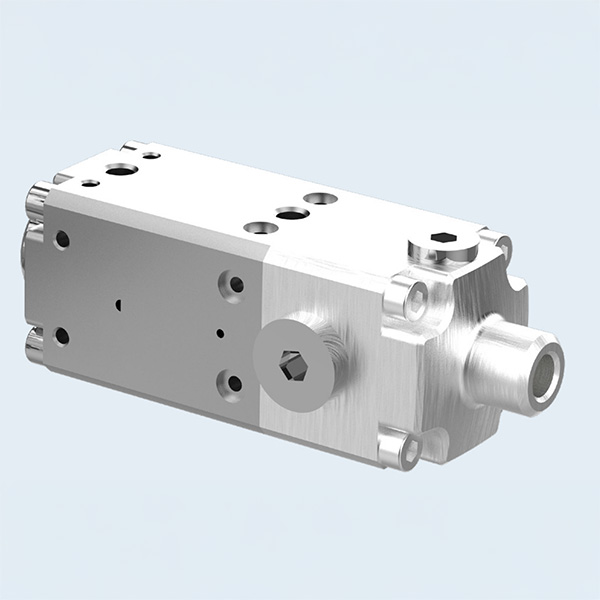

The WMAV diaphragm valve is designed for the precise and reliable dispensing of highly viscous materials such as polyurethanes, acrylics, epoxies, silicones, and fillers. Thanks to its innovative low-wear design and the possibility of integrating additional sensors and heaters, the WMAV valve offers a versatile solution for complex dispensing processes in modern production environments.

A distinctive feature of the WMAV valve is the “snuff-back” effect, which ensures a clean cut-off of the material, avoiding residual strings and improving application accuracy. The special diaphragm prevents air entry, protecting moisture-sensitive materials from premature hardening and reducing the risk of clogs or valve damages.

Made of resistant materials such as stainless steel (1.4301) and PTFE, the WMAV is highly resistant to abrasive and corrosive materials, extending the valve’s service life and reducing maintenance costs. The WMAV valve is suitable for working pressures up to 150 bar and offers precise dosage control through pressure and time adjustment. Furthermore, the integrated heating allows to adapt the material flow behavior to the specific needs of the process.